A Sustainable Christmas Tree from the 3D Printer

Projects, Research |

Simay Berber completed her bachelor’s degree in Mechanical Engineering at TUM and is currently in her fourth semester studying Aerospace at the TUM School of Engineering and Design. Since April, she has been working as a student assistant at the AM Tech Center of Airbus Helicopters, where she supports additive manufacturing projects - and has now realized a project that combines environmental awareness with high-tech.

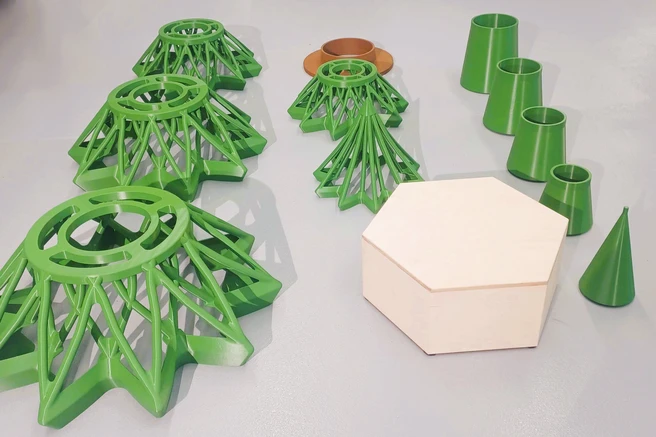

“The idea came from the city of Donauwörth, which wants to set up Christmas trees for the sustainable Christmas market on Plätzleweg. The requirements for the trees are demanding: they should have an appealing design and be durable, meaning usable for several years. That’s why we decided at the 3D printing center of Airbus Helicopters to show what is possible with additive manufacturing,” explains Berber.

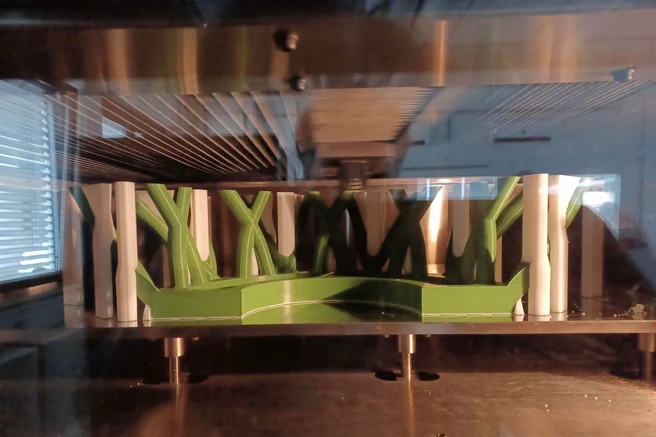

For the Christmas tree, the team used innovative materials: a plastic made from recycled components and a bio-based material derived from renewable resources. “Working with a material we don’t normally use was challenging. We had to adjust several printing parameters and revise design elements to make everything work. All the more rewarding it was to see that the finished tree turned out so well,” says Berber.

Berber was responsible for the design, while her colleagues handled the printing process and post-processing. The modular concept allows for space-saving storage and use over several years. “We didn’t just want a beautiful tree, but also a sustainable product that can withstand wind and weather,” she explains.

From Idea to Christmas Market

The printing of the 3D tree and the installation of all trees along Plätzleweg were accompanied by the TV show “Sendung mit der Maus.” The segment will air on December 21 in the Christmas episode on ARD and KiKa and will then be available in the media library.