Text: Susanne Hoecht

Pictures and video: Severin Schweiger

"I can help you," Anand Suresh told Alessia when they first met at a party last year. Alessia was born with a deformity in her right hand. Her hand is only partially formed, and her fingers are only at the base outlining the palm, a condition known as Symbrachydactyly. As a result, Alessia has limited use of her right hand. She learned to deal with her limitations by using her left hand more or by using her whole body. When Anand suggested developing a prosthetic hand that evening, it came as a big surprise to Alessia.

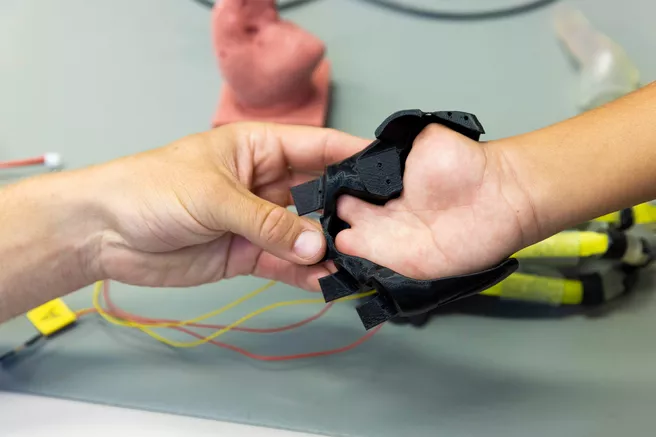

In Alessia's case, the challenge in manufacturing a hand prosthesis lies in the high degree of customization. With normal hand prostheses, there are only four standard sizes. The design is also only suitable for people with complete hand amputation, or transradial amputation. There is more room for adjustment with a standard prosthesis than is the situation with Alessia. In addition, her residual digits or remaining fingers bend at a different angle than is usual, limiting the movement of the prosthetic fingers. On top of that, the muscles in her forearm are weakened or atrophied due to limited usage. An electronically controlled prosthesis is therefore difficult for Alessia to wear, and not just for weight reasons. Also, very limited signals are picked up by the electrodes in the prosthesis to translate the electrical voltage generated in the muscle strands. But this is essential for the function of the electric prosthesis because it is the only way to open or close the hand as needed or to add other functions without invasive means.

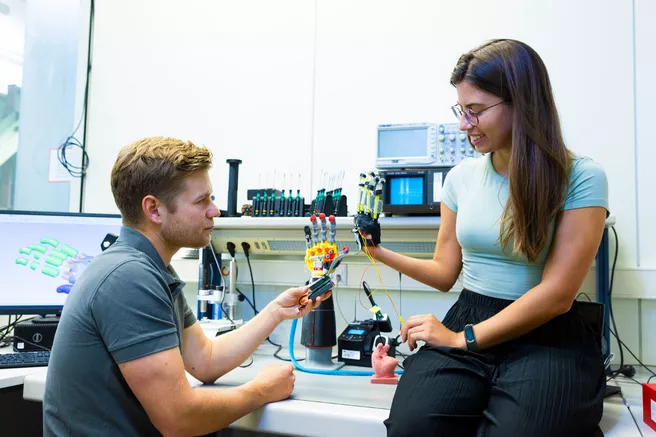

Anand Suresh thought the development of a highly complex and individual hand prosthesis was a good opportunity for students to apply their knowledge from their studies in practice. He, therefore, supervises student projects on this topic at the Laboratory for Product Development and Lightweight Design. One of the first students was Thomas Wegerer. He is studying for a master's degree in mechanical engineering and developed the first prototype of the prosthetic hand for Alessia as part of his term paper. Under Anand's guidance, Thomas did extensive 3D scanning and modeling of Alessia’s hand to create a fully customizable solution. He constructed a completely new finger design suitable for stereolithography (SLA) 3D printing, making it easy to customize. He implemented viable user and prosthetic interfaces, assembled the electronic building components, and programmed the hand’s function and he met with Alessia almost monthly to customize the prosthesis and get her feedback.

Alessia's initial prototype only allows her to hold larger objects. The prototype is extremely light and tailored to Alessia's hand anatomy despite having electronic control. This fundamental design, in Alessia's opinion, is "very cool." She would want to see the following improvements made to the prosthetic hand: She thinks that wearing comfort and handling when putting on and taking off could be enhanced in addition to visual features with less cables. In order to wash dishes by hand, she would also like to see a waterproof design.

Anand is also focusing on technical improvements to the prosthesis together with his students. One challenge still lies in the thumb. All of Alessia's metacarpophalangeal movement patterns are inherent in her thumb. However, her thumb is very primitive and only present at the base. By designing a thumb that works with Alessia's residual digit rather than bypassing it, Anand hopes to take advantage of this feature of her hand and enhance the prosthesis's functionality. This will be crucial for meeting complex requirements like the ability for Alessia to cut meat with her right hand in the future.

Meanwhile, Thomas Wegerer successfully completed his semester project with the first prototype of the hand prosthesis and handed it over to his successor and fellow student Elisa Schärer. For Thomas, the project was not only exciting from a technical point of view: "With this work, I had the opportunity to help someone in their everyday life. I also had creative as well as technical freedom to achieve the set goal." For Thomas, developing prostheses is an enjoyable and fulfilling task.

About:

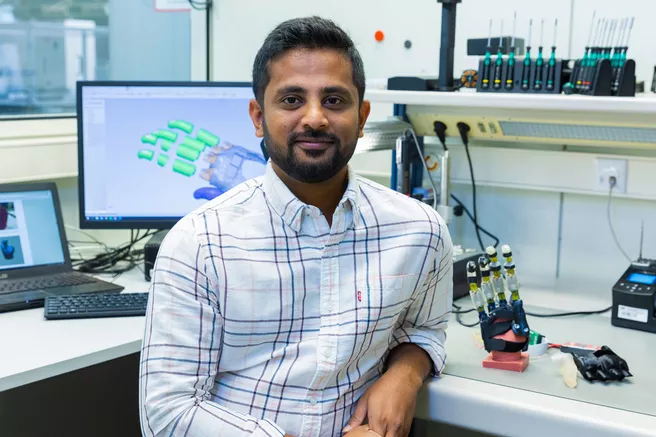

Dr. Anand Suresh has been involved in robotics since before his undergraduate studies. Before successfully completing his Ph.D. in Bioengineering and Robotics at the University of Genoa and the Italian Institute of Technology from 2014 to 2018, he received a double Master's degree from the Universities of Warsaw and Nantes.

Since 2018, he has been working as a postdoctoral researcher at the Laboratory for Product Development and Lightweight Design in the Department of Mechanical Engineering. There he leads the research group "Robot Systems". His current research focus is on human-centered robot development.

Links:

Profile of Dr. Anand Suresh:

https://www.mec.ed.tum.de/en/lpl/employees/current/anand-suresh/

Chair for Product Development and Lightweight Design:

https://www.mec.ed.tum.de/en/lpl/home/

Robotics research at the Laboratory for Product Development and Lightweight Design:

https://www.mec.ed.tum.de/en/lpl/research/research-groups/robot-systems/

About the Mechanical Engineering degree course, M.Sc.:

https://www.ed.tum.de/en/ed/studies/degree-programs/mechanical-engineering-m-sc/